Inspiring Applications of Best Laser Cutting for Global Industries

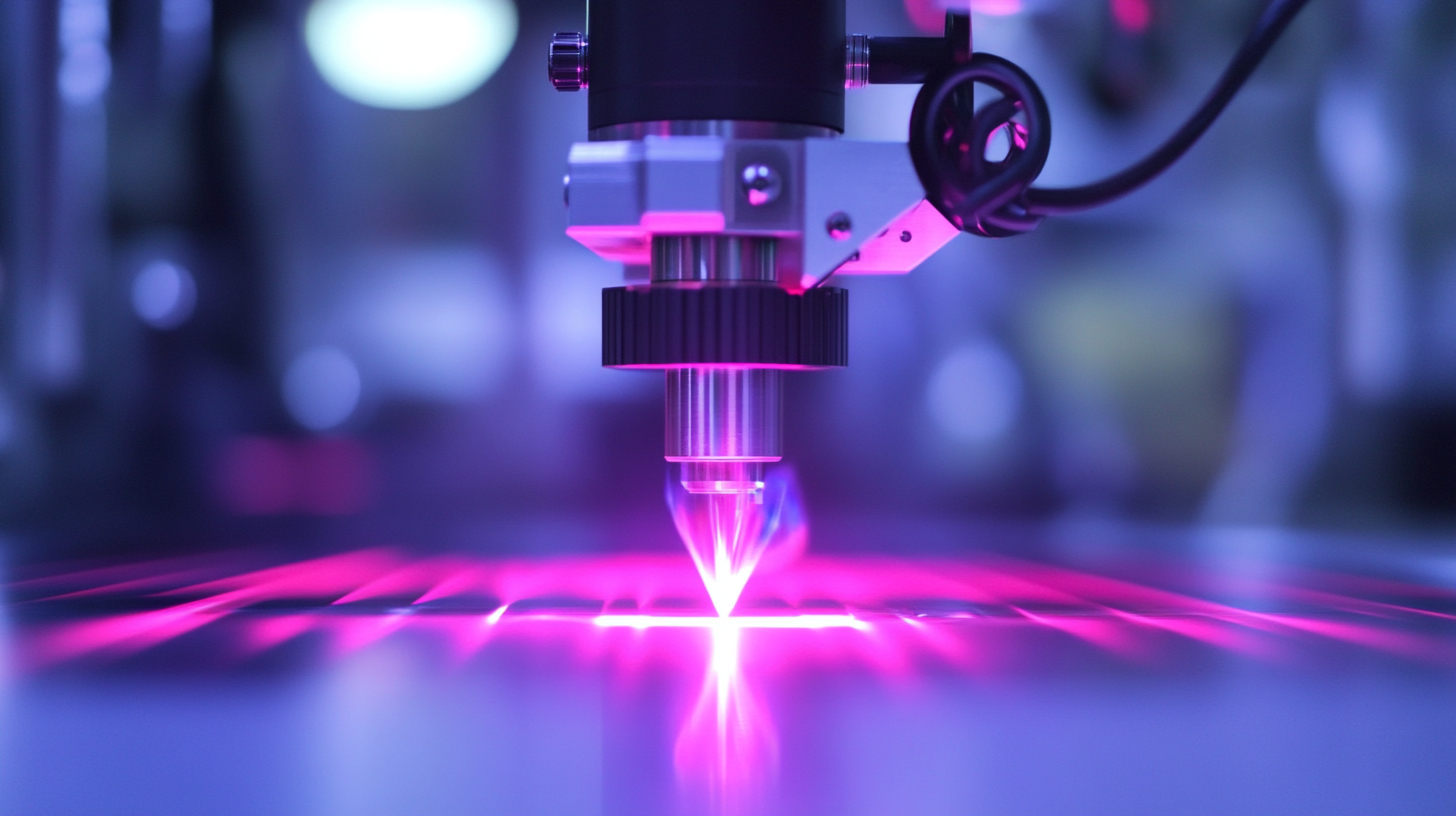

In today's rapidly evolving industrial landscape, laser cutting has emerged as a transformative technology, redefining precision and efficiency across various sectors. According to a report by MarketsandMarkets, the global laser cutting market is projected to grow from USD 4.4 billion in 2020 to USD 5.5 billion by 2025, reflecting a CAGR of 4.9%. This growth is fueled by the increasing demand for advanced manufacturing capabilities and the rising need for higher accuracy in production processes. Industries such as automotive, aerospace, and electronics are leveraging laser cutting for its unparalleled precision and versatility, revolutionizing how components are manufactured and assembled.

As we navigate the complexities of international trade, understanding the import and export certifications associated with laser cutting technologies becomes essential. In this blog, we will delve into inspiring applications of laser cutting in global industries and provide insights on navigating the associated regulatory landscape.

The Versatility of Laser Cutting: Applications Across Various Industries

Laser cutting technology has emerged as a transformative force across diverse industries, demonstrating its versatility in applications ranging from automotive to healthcare. According to a report by MarketsandMarkets, the global laser cutting market is projected to grow from $4.4 billion in 2023 to $6.8 billion by 2028, demonstrating a CAGR of 8.7%. This growth is driven by the increasing demand for precision and efficiency in manufacturing processes. For instance, in the automotive industry, laser cutting is utilized to create complex parts with minimal waste, contributing to cost reduction and improved production timelines.

Moreover, in the aerospace sector, where safety and precision are paramount, laser cutting enables the manufacture of intricate components that meet stringent regulatory standards. The aerospace materials market analysis highlights that advancements in laser technology are expected to enhance material quality and prototyping processes. Furthermore, the medical device industry benefits significantly from laser cutting, allowing for the creation of small, precise components that are essential for equipment such as surgical instruments. The precision laser cutting capabilities not only improve product quality but also enhance the overall reliability of medical tools, ultimately benefiting patient care. This demonstrates how laser cutting technology is not just a tool but a catalyst for innovation across various fields.

Key Materials Utilized in Laser Cutting and Their Unique Properties

Laser cutting technology has revolutionized industries by providing precision and efficiency in material processing. Key materials utilized in laser cutting include metals, plastics, and textiles, each with unique properties that enhance their suitability for various applications. For instance, metals like stainless steel and aluminum offer exceptional strength and durability, making them ideal for automotive and aerospace components. The ability of laser cutting to create intricate designs in these materials contributes to innovative product development.

In addition to metals, plastics such as acrylic and polycarbonate are increasingly favored in signage and display manufacturing. Their lightweight nature and versatility allow for creative designs, while the smooth finish achieved through laser cutting enhances aesthetic appeal. Textiles also benefit from this technology, particularly in the fashion and upholstery industries, where precision cuts can create complex patterns and shapes without fraying.

**Tip:** When choosing materials for laser cutting, consider the thickness and reflective properties. Thicker materials often require higher power settings, while reflective materials like copper may need specialized techniques to prevent damage to the laser. Proper material selection ensures efficient cutting and optimal results tailored to specific industry needs.

Material Utilization in Laser Cutting Across Industries

Advancements in Laser Technology and Their Impact on Product Precision

Advancements in laser technology have significantly transformed various global industries, enhancing product precision across manufacturing processes. For instance, the global laser cutting machine market is projected to reach $3.76 billion by 2025, according to a report by Allied Market Research. This growth highlights the increasing reliance on laser cutting applications in manufacturing, metalworking, and automotive sectors, where precision is paramount. The ability of lasers to cut through complex materials with minimal waste and high accuracy allows companies to produce intricate designs that were once deemed unfeasible.

One important tip for businesses looking to adopt laser cutting technology is to invest in training their workforce. Understanding the operational intricacies of laser machines can drastically improve production timelines and reduce errors. Moreover, according to a survey by MarketsandMarkets, organizations that implement continuous training programs report a 30% increase in both efficiency and quality of outputs.

Another consideration is to stay updated on the latest laser technology innovations. The integration of automation in laser cutting operations can help streamline workflows, leading to faster turnaround times and improved product quality. Research from TechNavio suggests that the automation of laser cutting processes can lead to a 25% reduction in operational costs, making it a strategic move for companies aiming to enhance their competitive edge.

Market Trends: Growing Demand for Laser-Cut Products in Global Manufacturing

The global manufacturing landscape is witnessing a significant shift as the demand for laser-cut products continues to surge. With the laser cutting machines market projected to grow from USD 5.89 billion in 2023 to USD 14.21 billion by 2033, at a CAGR of 9.21%, industries are increasingly recognizing the advantages of precision and speed that laser cutting offers. This technology not only enhances efficiency but also allows for intricate designs and minimal material wastage, making it a preferred choice across various sectors.

To capitalize on this growing trend, companies should focus on integrating advanced laser micromachining tools into their production lines. These tools are essential for diverse applications, including drilling, cutting, and engraving, thus enhancing versatility. Additionally, embracing technology advancements in laser systems will enable manufacturers to stay competitive in the evolving market.

Tip: Companies should regularly assess their production capabilities and invest in training their workforce to effectively utilize new laser technologies. This not only boosts productivity but also fosters a culture of innovation and continuous improvement within the organization. Moreover, collaborating with laser equipment manufacturers can provide valuable insights into optimizing operational workflows for better outcomes.

Sustainability in Laser Cutting: Eco-Friendly Practices and Innovations

In recent years, laser cutting technology has evolved not only in precision and efficiency but also in its commitment to sustainability. As industries across the globe seek to minimize their environmental impact, eco-friendly practices in laser cutting are becoming increasingly vital. By utilizing advanced machinery and innovative techniques, manufacturers are able to reduce waste materials significantly. The precision of laser cutting ensures that the amount of scrap generated is minimized, thereby conserving resources and reducing the overall carbon footprint of production processes.

In recent years, laser cutting technology has evolved not only in precision and efficiency but also in its commitment to sustainability. As industries across the globe seek to minimize their environmental impact, eco-friendly practices in laser cutting are becoming increasingly vital. By utilizing advanced machinery and innovative techniques, manufacturers are able to reduce waste materials significantly. The precision of laser cutting ensures that the amount of scrap generated is minimized, thereby conserving resources and reducing the overall carbon footprint of production processes.

Moreover, the advent of green materials and sustainable practices further enhances the effectiveness of laser cutting in promoting environmental responsibility. For example, manufacturers are now exploring biodegradable materials and recycled composites, which can be seamlessly processed with laser technology. This transition not only supports a circular economy but also aligns with consumer demands for greener products. Additionally, energy-efficient laser systems are being developed, incorporating features such as smart sensors and optimized cutting paths that consume less energy while maintaining high-output levels. As the adoption of these eco-friendly innovations grows, laser cutting stands at the forefront of sustainable manufacturing solutions.